With the European PV market riding the wave of the rapid transition to green energy, the adoption of PV power is becoming more common in people’s everyday lives, with this sustainable energy source presenting itself as a reliable and eco-friendly option for households and businesses alike. The significant growth rate of PV in Europe is a testament to the continent’s commitment to promoting clean energy systems and creating a low-carbon future. In recent years, there has been significant growth in the adoption of solar energy for applications including residential rooftops and balconies, with this trend driving the surge in demand for lightweight and flexible modules, which deliver the dual benefits of efficiency and portability.

The growing demand for end-user applications, including mobile phone charging, portable applications and fixed installations like the balconies already mentioned, has seen the development of flexible, efficient and lightweight solutions take on an increasing urgency.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

In response to these market forces, DuPont’s new Tedlar transparent frontsheet product, unveiled for the first time at the SNEC exhibition in June, provides high levels of protection for flexible PV modules, with DuPont and Desun PV subsequently jointly launching a flexible module deploying a Tedlar transparent frontsheet at Intersolar Europe. The product not only inherits the traditional advantages of the Tedlar family, but also achieves a significant leap in flexibility, durability and weight.

Statistics show that the annual market capacity for lightweight PV modules is estimated to exceed 10GW by 2030, supported by government policy and market demand, which will present Tedlar frontsheets with a broad market potential across the continent, according to Lucie Garreau, DuPont’s TS&D manager for Tedlar in the EMEA region.

The EU Solar Standards passed by the European Parliament mandates PV installations on buildings, with the boom in deployment of solar balconies in Germany also reflecting the European market’s commitment to sustainable development and the empowerment of individuals to generate their own electricity.

With this a trend aligning perfectly with the benefits offered by the Tedlar frontsheet, R&D investment in solar technologies such as vehicle-integrated PV has positioned it as a pivotal material in these cutting-edge applications.

Garreau points out that, with the increasing demand for flexibility and portability, the market for flexible PV modules in consumer applications is rapidly expanding. Active groups who value outdoor leisure are seeking sustainable and reliable power solutions through portable storage devices. Moreover, with the increasing occurrence of climate-related disasters, the need for off-grid power solutions has become ever more urgent. The combination of portable storage devices with flexible modules provides critical off-grid power solutions and ensures a continuous power supply in times of crisis. As a result, the potential consumer group for flexible solar products is diverse and varied, catering to camping enthusiasts, hikers, boaters and other groups who value eco-friendliness and self-sufficiency. The growing consumer market for flexible modules presents a promising opportunity for manufacturers to develop innovative designs and tailor-made solutions to cater to the unique needs of different consumer groups.

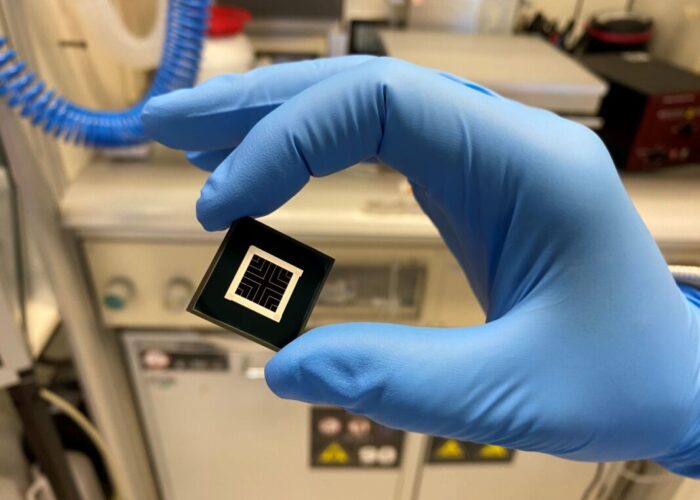

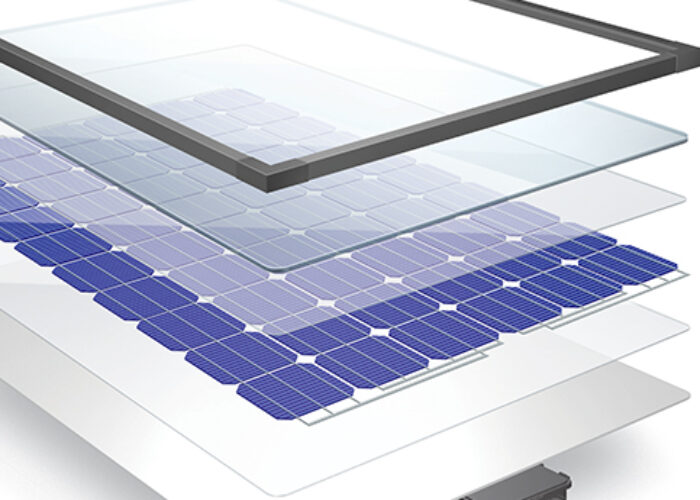

As a landmark innovation in the PV field, the Tedlar frontsheet possesses a range of advanced properties that can effectively enhance both the performance and service life of lightweight and flexible modules. In terms of material, the product is made from a partially fluorinated polymer—Tedlar polyvinyl fluoride (PVF), which is known for its exceptional durability, UV and weather resistance, with a high light transmittance to ensure optimal solar capture. At the same time, it has excellent mechanical strength and flexibility, which can effectively resist cracking, wear and harsh weather conditions.

Compared to the traditional module use of glass, Tedlar frontsheets have clear advantages in weight and flexibility. On one hand, they are lighter in weight, easy to install and conducive to weight-restricted applications and, on the other, their flexibility also offers possibilities for innovative designs, supporting use on curved surfaces where glass is not suitable.

Tedlar frontsheets are also wear- and bending-resistant and less likely to break, providing additional security. Chemical resistance ensures that they can withstand environmental pollutants without degradation, offering excellent protection for flexible modules.