China-based PV module manufacturer Sunport Power has officially started production at 1GW assembly plant using Eurotron’s MWT equipment for back-contact PV modules that reduce cell-to-module losses and boost module performance.

Sunport Power CEO, Dr Zhang said, “Back-contact modules come with substantial benefits. The most important being production capacity per panel in comparison to traditional methods. Thanks to our Eurotron production line that was already in operation, my clients already experience these advantages first-hand. Back-contact solar panels avoid capacity losses associated with shade and resistance in traditional panels. This means our clients generate more energy per square metre.”

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

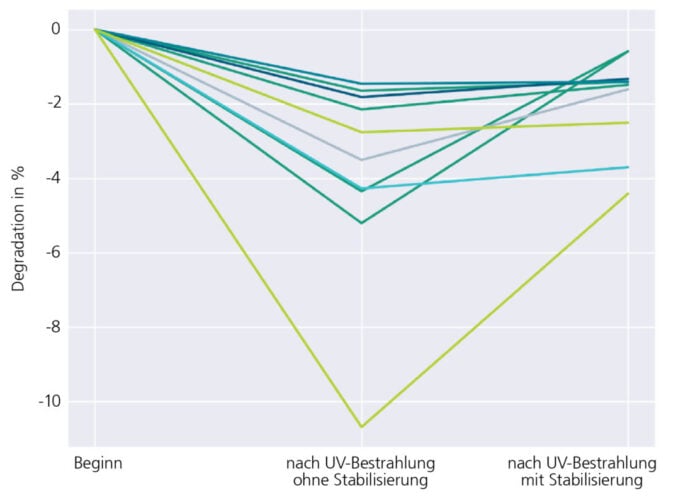

Compared to traditional modules, back-contact solar panels have also demonstrated improvement in accelerated lifetime tests. The Chinese factory will produce an annual 3.3 million solar panels.

Eurotron is a developer of back-contact solar cell processing equipment to provide lab to fab testing and pre-production services for MWT, EWT, HJBC and IBC solar cell/module technologies.