FuturaSun has launched its ‘ZEBRA’ Series n-type monocrystalline IBC (Interdigitated Back Contact) solar panel series to the residential PV and C&I markets across Europe. The new Zebra series offers a superior esthetics, enhanced electrical performance and a solid reliability and durability, a hallmark of IBC technology.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The PV market, especially concerning rooftop applications, whether commercial or residential, has always been sensitive to the need for peak module performance, aesthetics, solid warranty and most of all a consistent high energy yield to provide an acceptable energy payback period. However, the challenges of LID (Light Induced Degradation) impacting module performance in the initial first hours of operating exposure, as well the impact of Light and Elevated Temperature Induced Degradation (LeTID) phenomena, due to elevated high operating temperatures of the modules. Potential-induced degradation (PID) in crystalline photovoltaic modules, caused by so-called stray currents results in a number of ways p-type PERC (Passivated Emitter Rear Cell) technology can impact energy payback and overall performance, which can reduce the overall investment benefits in residential and C&I markets. As a result, such markets ability to lower LCOE and improve the IRR is restricted.

Solution

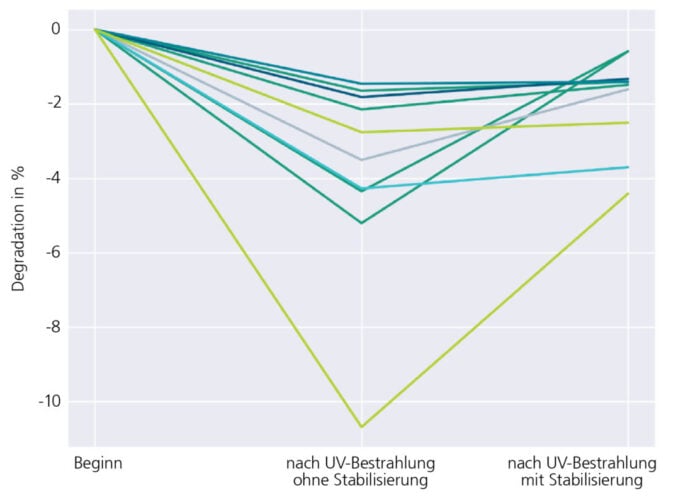

FuturaSun Zebra series modules use n-type monocrystalline (G1) 158.75mm x 158.75mm wafers, which are negative based using phosphorus doping that have 1 extra electron, limiting carrier mobility thus boosting conversion efficiency. The n-type silicon chemistry also makes the Zebra panel immune to performance limiting effects of LID and LeTID. The n-type modules are characterized by a low temperature coefficient which allows excellent module performance also at high temperatures, something that translates to a higher kWh production of the system. These attributes lead to higher, longer-term operating performance, shorter energy payback times and longer yield times that exceed other module types. Zebra series modules come with half cut IBC cells, reducing sheet resistance and improved micro-crack protection. The half-cut cells are assembled with an independent split section module design which secures a higher energy yield in case of partial shading and ensures the expected Voc and Isc that allow a canonical string design. The combination of technologies enables the conversion efficiency at module level to reach an industry-leading 21.28%. Superior low light performance inherent in IBC modules means the inverter is switched on earlier in the morning and switched off later in the evening, increasing overall yield. The POE (PolyOlephinicElastomer) encapsulation film significantly improves such characteristics as light transmittance, resistance to internal ionic drift and long-term optical, electrical and mechanical stability compared to the current market standard EVA (EthylenVinylAcetate). POE also creates an effective barrier against the effect of PID

Applications

Residential and C&I rooftop systems.

Platform

The ZEBRA IBC cells were developed by the International Solar Energy Research Center (ISC) Konstanz in Germany that feature lower cost screen printed firing-though contacts, no passivating contacts and rear-side only 3D-interconnection of fingers with busbars that enables compatibility with any wafer format and interconnection technology, generating cell conversion efficiencies of 23.5%. ZEBRA module dimensions (1004x1685x35 mm) are comparable to a standard 60-cell panel of 990mm x 1650mm typically used in rooftop installations, without the need for different rooftop designs, racking and handling solutions, compared with larger-area modules. The current top power class is 360Wp with a module efficiency of 21.287%. The ZEBRA series also comes in an ‘All Black’ offering as busbars and ribbons rear-side only and provide high-performance with module efficiencies of up to 20.69% and reach 340Wp to 350Wp. The temperature coefficient (TC) indicates the thermal module behavior, which is lower than many other technologies, having a TC of 0.3%/ °C, which is claimed to provide a 3% power gain in average operating conditions. The static load capacity is 5400 Pa while the static suction capacity is 3600 Pa. The first-year power warranty is an industry-leading 99% with a linear attenuation warranted to be not more than 0.4% per year starting from the second year and 89% at the end of 25th year The product warranty is set at 25 years.

Availability

Zebra series modules, both with white and black backsheet formats are currently available through local FuturaSun distributors in most EU countries.