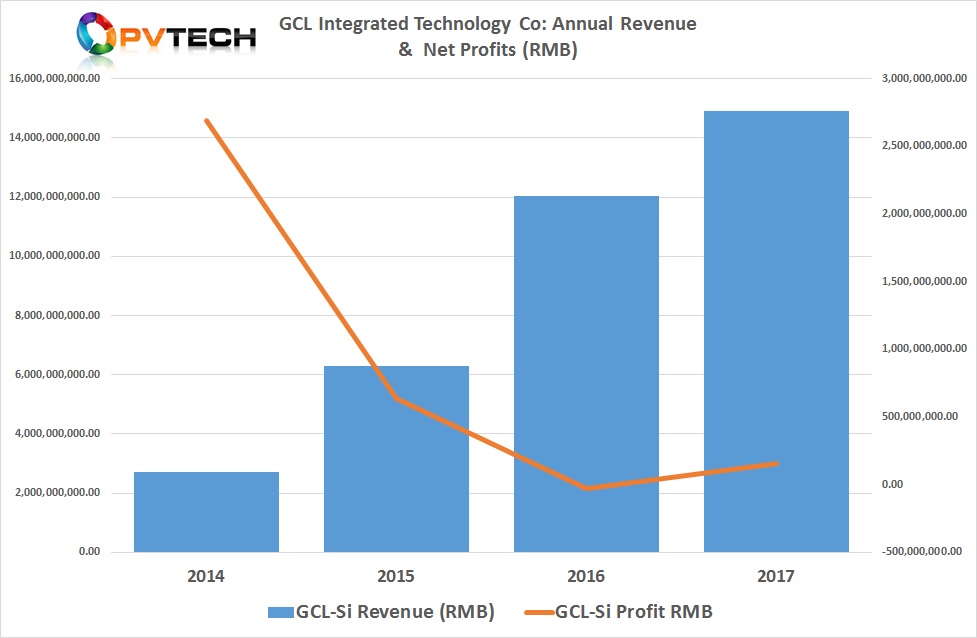

‘Silicon Module Super League’ (SMSL) member GCL System Integrated Technology (GCL-SI) has reported preliminary unaudited ‘express’ 2017 financial results, highlighting revenue growth to record levels in the fourth quarter and the return to profitability.

GCL-SI reported full-year 2017 revenue of approximately RMB 14.49 billion (US$2.3 billion), an increase of 24.03% from 2016.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The company had posted record second quarter revenue of around US$608 million, leading to a return to profitability in first half of the year, due to PV module ASP stability and concerted manufacturing cost cutting, including increasing cell conversion efficiencies.

The company had also benefited from the continued strong growth in PV installations in China, which in the first half 2017 reached 24.4GW and over 53GW for the full-year.

However, third quarter sales declined around 25% from the second quarter of 2017, indicating softening demand for utility-scale projects in China after FiT regressions mid-year.

The full-year results indicate that fourth quarter sales increased around 103% from the previous quarter.

GCL-SI noted in the express financial report that the overall sales increase was primarily due to the strong ramp of high-efficiency solar cells used in its modules and the subsequent strong demand for the products.

The company also reported a small preliminary gross profit for 2017 of approximately RMB156.9 million (US$24.7 million), which was due to the higher shipments overseas and cost reduction strategies such as a reduction in capital expenditures and lower production costs supported by higher cell and module conversion efficiencies.