Heraeus Photovoltaics has introduced specially developed metallization pastes for ‘knotless screen’ printing of solar cells. The new SOL9641AX/BX series is designed to realise the full advantages of knotless printing screens and were developed in close collaboration with screen vendors and customers. Chinese PV manufacturer EGing became the first integrated photovoltaic manufacturer worldwide using knotless screen printing in mass production of c-Si solar cells.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

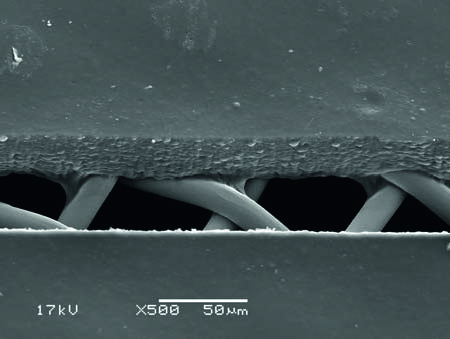

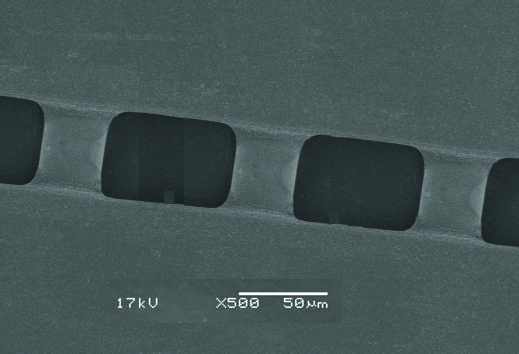

Different from the conventional metal wire mesh, the knotless screen with so-called ‘zero degree mesh’ can give more room for silver paste to go through the mesh compared to conventional screens, while conventional screens usually need adjustment on its printability. However, specially developed metallization pastes are required to maximize the key benefits of knotless screen printing to obtain higher aspect ratio on ultra-fine-line fingers.

Solution

The SOL9641AX and SOL9641BX have been built on two product platforms 9641A and 9641B with the latest breakthrough in organic vehicle system designed for knotless screen with finer fingers than printing though conventional screen. Both 9641AX and 9641BX provide conversion efficiency gains by only the switch in screens, which gives great cost advantage. Compared to conventional paste, 9641AX and 9641BX could achieve much better aspect ratio (AR) for fired fingers (0.3 AR VS 0.5 AR), which results a gain in Isc and FF, therefore providing efficiency improvement. Heraeus said that a 0.1% efficiency gain can be achieved and the pastes are perfectly suited also for black silicon texturing.

Applications

SOL9641AX is suitable for black-silicon with excellent adhesion, while SOL9641BX has a wide process window for PERC and Ultra-lightly-doped-emitters. SOL9641 is compatible with both monocrystalline and multicrystalline wafers.

Platform

The printability of SOL9641AX/BX has been specifically tailored to knotless screens. It features a unique paste rheology, enabling a significant higher aspect ratio on ultra-fine-line fingers, which can print defect-free through a less than 26μm screen opening in high throughput mass production. Paired with Heraeus’ ‘floating busbar paste’ SOL9622B, further efficiency gains are achieved, compared to conventional pastes. The new pastes are typically dried in an IR dryer with set points of 250 – 300° C in less than 30 seconds or 150 – 200° C for 10 minutes in circulated air oven.

Availability

April 2017, onwards.