Earlier this month, the leading Chinese PV producer LONGi hosted a ‘utility day’ event at an exclusive venue in London, UK, to celebrate the launch of its latest module, the Hi-MO 9. The event was an opportunity for LONGi to bring together a selection of its long-term clients and other partners for a close look at the Hi-MO 9’s many features.

The Hi-MO 9 is the latest incarnation of LONGi’s cutting-edge hybrid passivated back contact (HPBC) technology, first launched in 2022. This coincided with a period during which much of the industry was transitioning to heterojunction (HJT) or tunnel oxide passivated contact (TOPCon) cells. The company’s stated belief is that back contact technology offers even greater potential efficiency gains than either HJT or TOPCon technologies and will help drive crystalline silicon PV technology close to its theoretical upper limit.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

Before the event, PV Tech spoke with Leon Zhang, president of LONGi Europe, to learn more about what sets the Hi-MO 9 apart and why LONGi believes HPBC may prove to be the “ultimate” c-Si technology.

PV Tech: Longi has placed significant emphasis on its belief that back contact is the future and will lead towards the ultimate fulfilment of crystalline silicon PV technology’s efficiency potential. Why is this and what does it offer versus other dominant technologies in the industry such as TOPCon?

Leon Zhang: LONGi considers back contact (BC) technology as the future of crystalline silicon PV in view of its great potential for efficiency maximisation. The theoretical efficiency limit for crystalline silicon solar cells is commonly viewed as 29%; LONGi BC cells have already achieved 26.5%. That means LONGi has already reached over 91% of the theoretical efficiency limit. BC technology therefore represents the ultimate technology route in our view.

Compared with TOPCon, BC can offer higher efficiency by minimising shading and resistive losses on the front side of the cell, enhance reliability, lower temperature co-efficiency and operating temperatures, lower annual degradation rate and ultimately increase the power generation.

BC is also a versatile platform technology which is compatible with TOPCon and HJT technologies, meaning that we can look at combining these technologies to see further advancement. This compatibility positions BC as a leading choice for the highest cell efficiency.

Last year you launched your hybrid passivated back contact technology and stated that all of your panel production would eventually employ this technology. Please explain in more detail what this technology is, what advantages it offers and why it’s an important step for LONGi to embrace this technology.

Hybrid passivated back contact (HPBC) technology is a state-of-the-art technique that integrates back contact with hybrid passivation methods. The back contact design facilitates a busbar-free front surface, thereby reducing shading effects and enhancing module efficiency. Additionally, it mitigates ribbon stress, which in turn improves the product’s reliability.

On the rear side of the cell, HPBC employs a hybrid passivated back contact structure that significantly decreases metal recombination and contact resistance. This design brings the cell’s structure much closer to achieving the theoretically calculated efficiency in industrial terms. Consequently, hybrid passivation is a creative enhancement to the cell’s conversion efficiency.

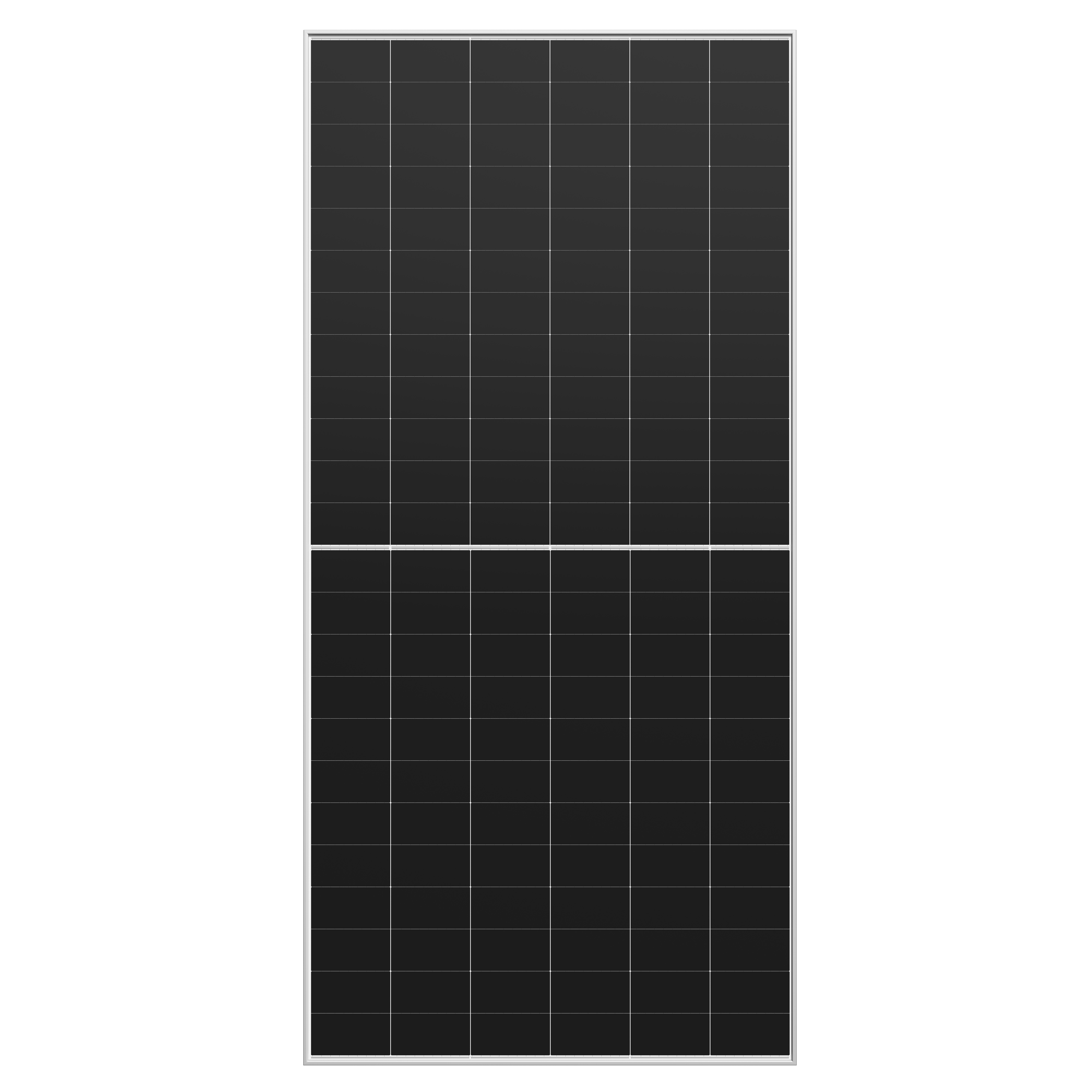

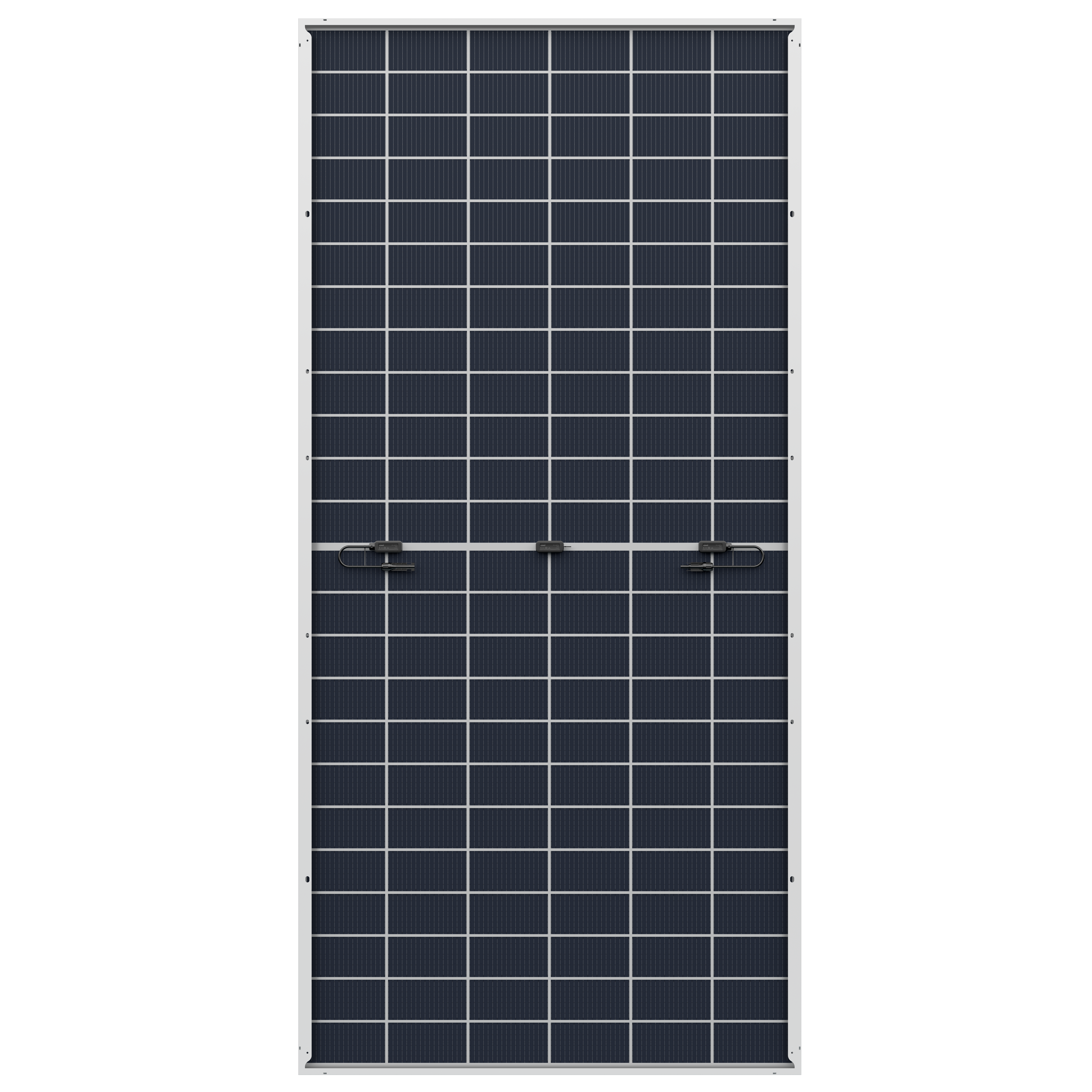

The Hi-MO 9’s back contact design results in a busbar-free front surface, minimising shading losses. Image: LONGi.

Your latest module launch, the Hi-MO 9, is based on HPBC technology. Please provide us with some insights into the Hi-MO 9 and the key features that set it apart.

The Hi-MO 9, with its high efficiency of 24.4%, is the highest in the industry while maintaining the same module size of 2382*1134mm as the Hi-MO 7. The output power can be up to 660W. Meanwhile, Hi-MO 9 has low yearly degradation of -0.35%, and a good temperature coefficient of -0.26%/C, ensuring 30 years of high power generation. It also offers higher reliability performance over the module’s entire lifecycle thanks to the thicker wafer, flat-shaped welding, effective resistance of uneven irradiation, digital production process and stringent quality control.

When do you expect to complete the full transition to back contact technology in your modules?

Since 2022, LONGi has used ‘Back Contact 1.0’ technology in products and thereafter kept increasing BC capacity percentage compared to traditional technologies like PERC and TOPCon. This strategic balance ensures we can fulfil the diverse needs of the global market. Due to the above-mentioned advantages of BC, we firmly believe more and more customers will look to BC as their premier choice and preferred option from an IRR perspective. We will reach 70GW BC capacity by end of 2025 and will keep shifting our global capacity to BC afterwards.

As we know, the solar industry is incredibly price sensitive, and advances such as your shift to HPBC technology can come at a premium for buyers. How does the Hi-MO 9 strike a balance between cost-effectiveness and technological advancement to ensure a realistic price point that the market will accept?

As previously highlighted, the Hi-MO 9 delivers a multitude of benefits on efficiency, reliability and, ultimately, increased power generation. These quantifiable advantages provide significant value to our customers, exemplified by increased power generation by 6-8%, reduced balance of system costs by 3% and a decreased levelised cost of electricity by 4-7% compared to TOPCon. These quantifiable benefits guarantee our customers’ better investment returns in a reliable way. We have chosen a price premium for the Hi-MO 9 because of the above quantified benefits for customers—making it a win-win scenario. This way LONGi can continue to make consistent R&D investment to keep shaping the world and accelerate the net zero process.

Almost as important as the power a PV module produces is its reliability and durability in a range of sometimes extreme weather conditions. Please could you give some insights into the testing the Hi-Mo 9 has undergone and how well it performs in conditions such as high wind, hail etc.?

The Hi-MO 9 possesses several inherent advantages when it comes to reliability, such as lower cell edge stress thanks to the back contact one-line welding structure which reduces welding stresses by 50%. Field tests have also demonstrated that Hi-MO 9 operates at temperatures that are 0.5℃ lower than comparable products, thanks to its higher efficiency, which in turn enhances the product’s reliability throughout its entire life cycle and that of the PV plant. The Hi-MO 9 also incorporates LONGi’s TaiRay Wafer, which is able to withstand a maximum stress level 16% higher than standard wafers.

In response to various environmental challenges such as hail, we are developing a Hi-MO 9-based product designed to resist impacts from hailstones with a diameter of up to 55mm. We aim to launch this product to the market soon. More scenario-based products such as wind-resistant, anti-dust and agrivoltaic solutions are also on the way as we speak.

Another area where PV manufacturers are coming under closer scrutiny is their performance against a range of environmental, social and governance (ESG) measures. Please outline some of the key areas where LONGi is taking a lead in terms of its ESG practices?

LONGi has embedded sustainability across our company, products and operational practices. LONGi’s own greenhouse gas emissions reduction targets and those of our partners have been validated by SBTi [Science Based Targets initiative], making us the first Chinese PV manufacturer to secure such validation.

We set a high social responsibility standard for ourselves and require the same of our supply chain partners, based on international principles of the UNGP [United Nations Global Compact], ILO [International Labour Organization] and OECD [Organisation for Economic Co-operation and Development]. And we have put in place strict governance to ensure compliance and business sustainability.

Finally, through honest and transparent reporting and by benchmarking our ESG performance against the best-in-class companies worldwide such as Apple, LONGi leads the PV industry in various ESG metrics and supports our global customers in meeting their own high standards.

In influencing a customer’s decision to purchase your modules versus a competitor’s, how important are ESG considerations?

When customers choose LONGi, they select a manufacturer they trust to fulfil all their ESG obligations, both legally and in terms of performance standards. The CSRD (Corporate Sustainability Reporting Directive) and CSDDD (Corporate Sustainability Due Diligence Directive) already require our customers to engage in ESG reporting.

LONGi’s Sustainability Report and Climate Whitepaper are crafted based on internationally recognised standards and contain the necessary datasets for meeting ESRS reporting obligations. Looking further ahead, LONGi’s R&D teams have integrated considerations of product carbon footprint, eco-design and the elimination of toxic PFAS materials into product design. These initiatives help us to future-proof our ability to meet the ESG requirements of our customers.

Your facility at Jiaxing has been selected as a Global Lighthouse Factory by the World Economic Forum for its pioneering use of technologies such as artificial intelligence to streamline production processes. What is the significance of this accolade and how do you hope it might serve as an example to the rest of the industry of what 21st century hi-tech manufacturing looks like?

Indeed, our Jiaxing factory is the first and only one in the PV industry to be recognised among Global Lighthouse Factories. This achievement highlights our leadership in advanced manufacturing ability and experience, characterised by innovative applications of AI, machine vision and data-driven processes that optimise production and quality.

Through the application of cutting-edge technologies like automation, Internet of Things and Big Data, our Jiaxing facility has seen remarkable improvements: a reduction in the delivery cycle by 84%, energy consumption by 20%, and production loss by 43%. This results in an average production rate of one photovoltaic module every 18 seconds.

LONGi’s commitment to manufacturing excellence is evident in our industry-leading cell allocation and monitoring systems. These ensure the delivery of products with precise power specifications and superior quality, achieved through comprehensive AI-assisted quality inspection and proactive issue resolution.

The customer-centric values delivered by our Jiaxing facility exemplify our commitment to Smart Manufacturing and Industry 4.0 principles. We are confident that our approach will inspire a new era of digital transformation within the PV industry, enhancing production efficiency, promoting lean manufacturing, and driving towards green, low-carbon and sustainable development.

Longi played a key role several years ago in leading the industry’s shift from polycrystalline to monocrystalline silicon. To what extent do you believe that your adoption of back contact technology will have a similar impact in the industry?

BC technology is set to be a pivotal milestone in the evolution of the photovoltaic industry, and LONGi’s uptake of this technology will mirror our pivotal role in the industry’s shift from polycrystalline to monocrystalline technology through our development of RCZ technology and diamond wire cutting.

Over the past seven years, we have dedicated ourselves to the development of BC technology, with over one thousand R&D experts actively engaged in research and pilot production. In the last five years, LONGi’s accumulative R&D investment has exceeded RMB23.5 billion, yielding hundreds of patents in BC technology. LONGi is confident that back contact technology is the next game changer in the PV industry.

What are your expectations of the likely growth of back contact technology in 2025 and beyond?

We firmly believe that BC technology will become the dominant technology in the market from 2025 onward, with LONGi paving the way for mass production and establishing the necessary ecosystem. We expect BC technology to be widely integrated across all installation segments, from residential to commercial and industrial and utility-scale projects, driven by the push for higher energy yields and reduced costs per watt.