Three of the solar industry’s leading manufacturers have launched a standardisation drive aimed at creating a standard for module sizing and mounting hole spacing.

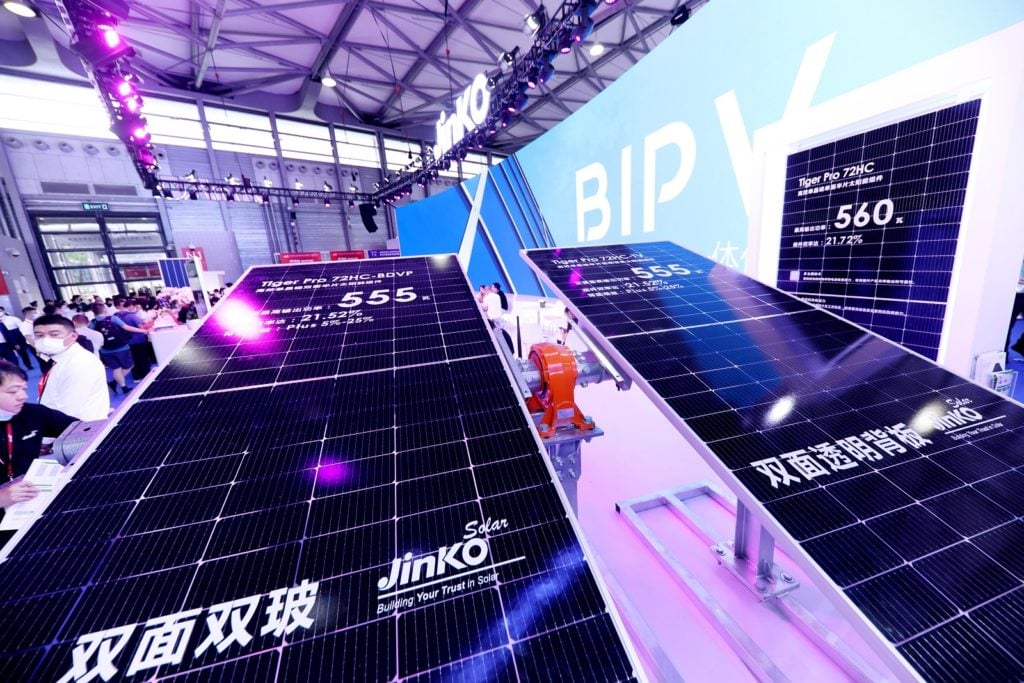

LONGi Solar, JinkoSolar and JA Solar, the three ‘Solar Module Super League’ (SMSL) manufacturers to have jointly launched the M10 type, 182mm wafer last year, have reached a consensus on the ideal size of modules and mounting hole spacing in order to “jointly advocate and promote the standardisation of healthy development of [the] PV industry”, the trio said.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The following schematics have been agreed upon as per the consensus.

- 54-cell modules – 1,722mm x 1,134mm; mounting hole spacing: 1,400mm

- 72-cell modules – 2,278mm x 1,134mm; mounting hole spacing: 400mm, 1,400mm

- 78-cell modules – 2,465mm x 1,134mm; mounting hole spacing: 400mm, 1,200mm/1,500mm

In a statement, the three manufacturers said that while the M10 wafer’s 182mm size was agreed upon last year, differences in technical roadmaps, design concepts and installation modes had created modules of varying sizes using the same technology.

“This makes it difficult to standardize component specifications and reduce manufacturing costs. As a result, the upstream and downstream coordination is getting affected in addition to system design and installation issues,” the statement read.

There have been further calls within the sector for greater standardisation of products, especially in relation to racking and mounting, in order to align the industry on approaches to reducing microcracks during both construction and operation of utility-scale PV projects.