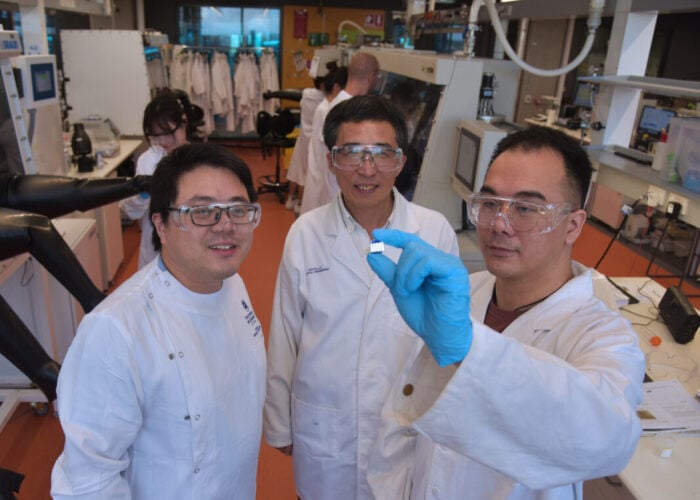

Natcore Technology scientists working at Ohio State University have continued to make progress on the development of the company's liquid phase deposition (LPD) process, demonstrating it can be used to apply an antireflective coating to textured solar cells as well as standard planar cells. The company said this could help open the door for the industry to achieve even further wafer thickness reductions by eliminating the thermal vacuum AR coating process.

Once solar cells are texturized, they are put through the remaining standard cell processing steps, which include adding the AR coating and the contacts. A growing problem, however, is that the conventional coating process requires the cells to travel through a vacuum furnace. As the wafers get thinner, the existing AR process causes them to warp, reducing the yield from the production process.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

Measurements made at NASA Glenn Research Center in Cleveland show that the reflectance from texturized wafers coated with Natcore's LPD AR coating is reduced to well below 2% over the entire absorption band of silicon cells–a two-thirds reduction from the typical reflectance achieved by standard industry practices and a result that would be accompanied by an increase in cell efficiency.

(For solar cells, the optimum reflectance is zero; a typical industry reflectance is about 6%. Reflectance is the proportion of light hitting a surface that is reflected from it.)

“The processing steps for achieving this outstanding result will be implemented in the intelligent processing tool we're building in Silicon Valley,” says Brien Lundin, chairman of Natcore. “We've had strong interest in this technology from several solar cell companies in China. We'll send a number of coated wafers for each of them to process into finished solar cells before we take orders for the industrial version of our intelligent processing tool.”

Natcore also recently announced its choice of the Kodak research labs in Rochester, NY, as the location of its new R&D center.