Further study is needed to reduce the recycling costs and environmental impact of used solar panels, according to scientists at the National Renewable Energy Laboratory (NREL).

The researchers warn there is currently no plan for how to manage PV modules at the end of their 30-year lifespan, and predict the volume of modules no longer needed could reach 80 million tonnes by 2050.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

NREL, the US Department of Energy's primary national laboratory for renewable energy and energy efficiency research and development, said its findings form part of the first global assessment into the most promising approaches to end-of-life management for PV modules.

“PV is a major part of the energy transition,” said Garvin Heath, a senior scientist at NREL. “We must be good stewards of these materials and develop a circular economy for PV modules.” Heath is lead author of ‘Research and development priorities for silicon photovoltaic module recycling supporting a circular economy’, which appears in the journal Nature Energy.

In addition to quantity, the nature of the waste also poses challenges. PV modules are made of valuable, precious, critical and toxic materials. There is currently no standard for how to recycle the valuable ones and mitigate the toxic ones.

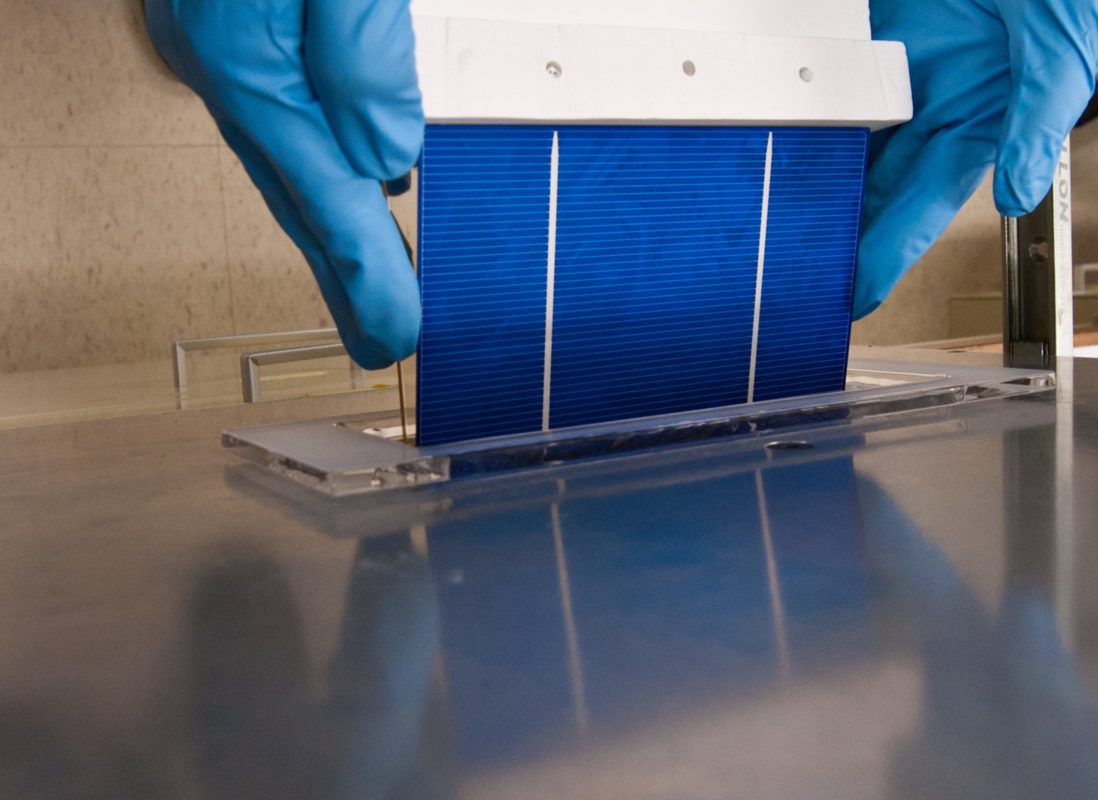

The authors focused on the recycling of crystalline silicon, a material used in more than 90% of installed PV systems in a very pure form. It accounts for about half of the energy, carbon footprint, and cost to produce PV modules, but only a small portion of their mass. Silicon’s value is determined by its purity.

“It takes a lot of investment to make silicon pure,” said Timothy Silverman of NREL. “For a PV module, you take these silicon cells, seal them up in a weatherproof package where they’re touching other materials and wait 20 to 30 years – all the while, PV technology is improving. How can we get back that energy and material investment in the best way for the environment?”

The authors found some countries have PV recycling regulations in place, while others are just beginning to consider solutions. Currently, only one crystalline silicon PV-dedicated recycling facility exists in the world due to the limited amount of waste being produced today.

Based on their findings, the research team recommends a focus on the recovery of high-value silicon versus intact silicon wafers. The latter has been touted as achievable, but silicon wafers can crack and may not meet today’s standards to enable direct reuse. To recover high-value silicon, the authors highlight the need for research and development of silicon purification processes.

Finally, the authors note that finding ways to avoid waste to begin with is an important part of the equation, including how to make solar panels last longer, use materials more effectively and produce electricity more efficiently.

“We need research and development because the accumulation of waste will sneak up on us,” Silverman said. “Much like the exponential growth of PV installations, it will seem to move slowly and then rapidly accelerate. By the time there’s enough waste to open a PV-dedicated facility, we need to have already studied the proper process.”