REC Silicon will negotiate a raw material supply agreement with silicon metal provider Ferroglobe as part of a new collaboration between the companies aimed at building a US-based solar supply chain.

Norwegian polysilicon manufacturer REC Silicon said Ferroglobe will be a critical partner in ensuring a steady supply of fully traceable metallurgical grade silicon metal produced in the US.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

UK-headquartered Ferroglobe announced last month that it has restarted its second furnace at its Selma facility in Alabama, US, taking the site’s total annual silicon metal capacity to 22,000 tons.

The news comes after South Korean chemical company Hanwha Solutions increased its stake in REC Silicon to 21.34% earlier this year as it looks to reopen the firm’s Moses Lake polysilicon facility in Washington state.

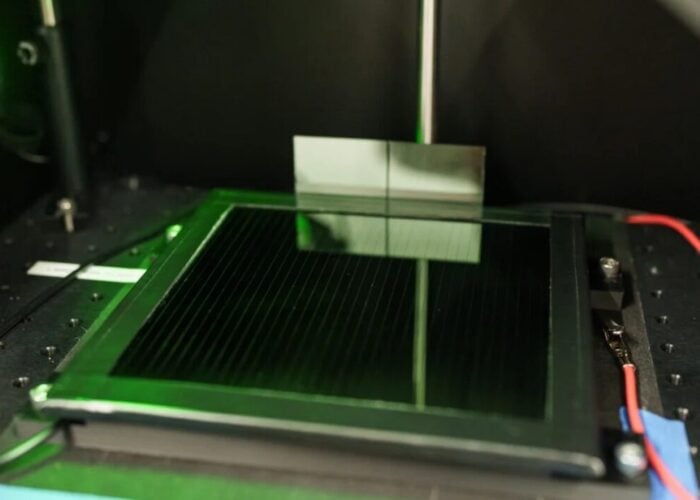

Polysilicon production using fluidised bed reactor technology is on track to start at the facility during Q4 2023, ramping to full capacity during 2024, REC Silicon CEO James May revealed last month.

REC said in a press release today that Hanwha’s investment has “sparked the impetus” to expand REC’s long-standing relationship with Ferroglobe and plan for the immediate development of an end-to-end US solar supply chain from raw silicon to polysilicon and modules.

Polysilicon produced at Moses Lake will be used by Hanwha Solutions’ PV module manufacturing division Qcells, which currently operates a 1.7GW module factory in the state of Georgia.

The memorandum of understanding between REC Silicon and Ferroglobe commits the companies to work together to increase production and employment at each of their facilities.

REC said the development of an end-to-end solar supply chain in the US would immediately be possible if the Solar Energy Manufacturing for America (SEMA) act were passed.

Initially unveiled last year by the senator for Georgia, Jon Ossoff, and included in Joe Biden’s stalled Build Back Better policy agenda, SEMA proposes a series of tax incentives, rewarding manufacturers of polysilicon, ingots, wafers, cells and modules for setting up facilities in the US.

“REC is committed to driving large-scale investments in the United States, and we believe that the passage of SEMA in particular would result in the creation of tens of thousands of high-paying manufacturing jobs across the sector, accelerating the US transition to clean energy,” said May.