Researchers at the University of Sheffield have found a new way to extend the life of perovskite materials by more than three months, paving the way for new solar cell technologies to be manufactured in a less wasteful fashion.

Perovskite materials’ lifespan can be extended from much less than a month to more than four if they are stored at low temperatures, according to scientists at the University of Sheffield’s Energy Institute and Department of Physics and Astronomy.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

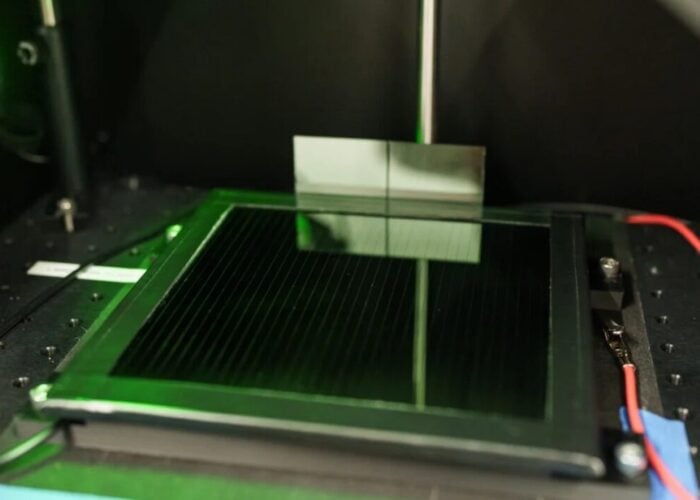

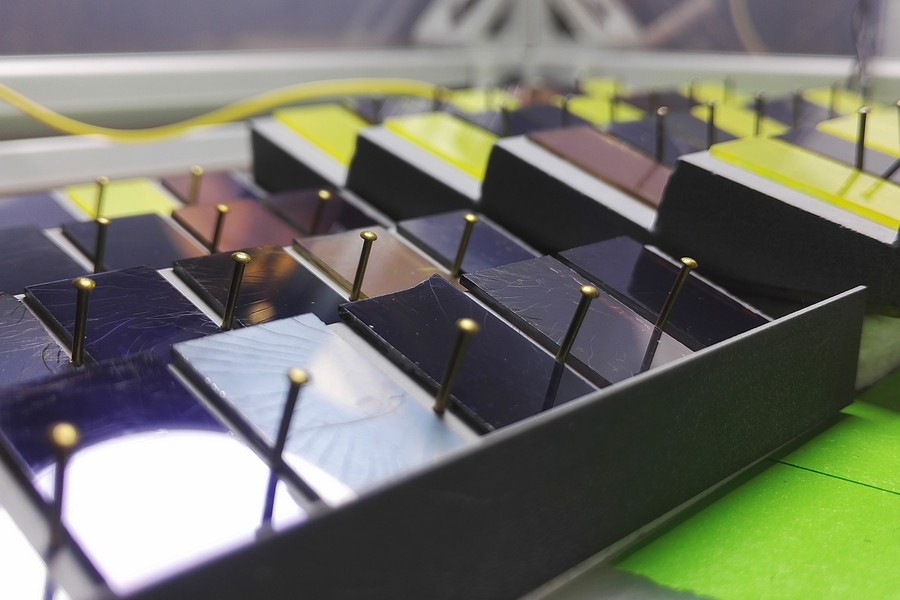

The researchers worked with the university’s tech spinout, Ossila Ltd, to conduct a series of experiments that focused on the stability of perovskite precursor solutions; the light-absorbing layer which is positioned between those used to extract current from the cell. Some solutions were kept at room temperature, while others were refrigerated at four degrees Celsius for varying time periods, before they were used to make prototype solar cells.

Due to the shorter lifespan of current perovskite solar cells, many companies face difficulty maintaining production capacity if they cannot rely on a consistent supply of precursor solutions. Sheffield’s Department of Physics and Astronomy researcher David Lidzey said the findings, which were published in the journal ChemSusChem, show that storing solutions at low temperatures enables companies to side-step the issue altogether.

As well as temperature, the researchers also looked at the structure and composition of the perovskite films made with the solutions produced, which enabled them to identify several key reactions that caused their degradation, said lead PhD researcher Mary O’Kane.

Making perovskites more durable has become a focal point of several university studies over the past year after both the European Commission and US Department of Energy pledged to support the growth of domestic solar manufacturing markets. Scientists from Queensland University of Technology (QUT) used hair clippings from a barber shop to form an “armour” that increases the material’s power conversion efficiency last month, while a team at the Massachusetts Institute of Technology (MIT) applied a “data fusion” process to test different formulations and assess their longevity. More recently, a joint study by researchers at the University of Bath and Imperial College London examined how important the selection of separate layers within perovskite can prevent degradation.