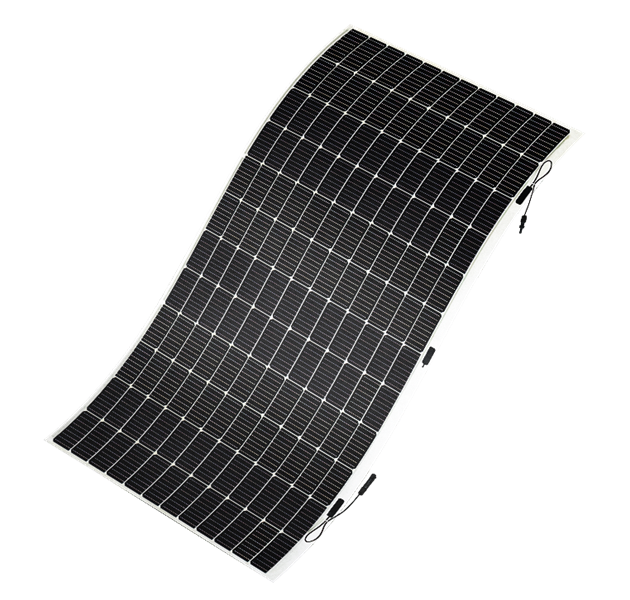

An estimated 40% of commercial and industrial buildings are unable to sustain the weight of a typical PV system using glass modules. This effectively locks a large swathe of potential PV users out of the market, ones that arguably stand to gain most from the benefits self-generated solar power has to offer.

To open up the market, Sunman Energy has developed a lightweight PV module that does away with glass altogether, offering significant weight savings versus traditional glass-based modules. Thomas Bell, Sunman’s director of global product marketing, discusses the company’s technology and his views on the future evolution of the global C&I rooftop market.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

PV Tech: Where did the original idea for Sunman’s lightweight modules come from?

Thomas Bell: The original idea for Sunman’s lightweight modules stemmed from recognising the need to overcome the limitations imposed by traditional glass PV systems, particularly regarding rooftop load-bearing issues that can prevent the installation of PV systems. We saw an opportunity to innovate by developing a glass-free, lightweight alternative.

We identified a significant market gap for solar solutions that could be deployed on structures with limited load-bearing capacity, thereby driving the development of our innovative lightweight technology. Sunman is committed to providing customers with a all type of roofing solutions, achieving ’PV Everywhere’.

Please describe some of the technical details of your product; how does it differ to a typical crystalline silicon PV module?

Unlike traditional PV systems, which are encased in heavy glass, Sunman modules utilise high-efficiency crystalline silicon technology combined with lightweight polymer composites and a proprietary encapsulation technology that meets the certification standards of traditional components, ensuring reliability and performance.

Our modules weigh only 2.8kg/m²—about 30% of traditional modules—and are only 2mm thick. This ultra-lightweight design enhances transport efficiency, reduces installation time and costs and allows for easy customisation in shape and size, which traditional modules cannot accommodate.

Can you give a sense of the scale of potential PV users that are, in effect, locked out of the market because of the load-bearing limitations of C&I rooftops?

Current estimates suggest that nearly 40% of commercial and industrial rooftops cannot support traditional glass modules due to structural load limitations. This equates to millions of potential users globally—businesses that want to harness solar energy but are constrained by their building designs. The barriers are particularly pronounced in urban areas where roof space is often limited and load-bearing capacities are inadequate.

How does your product help in unlocking these opportunities?

Sunman’s lightweight eArc modules effectively unlock opportunities for solar installations on low-load-bearing rooftops. They are ultra-light, safe and can be customised to meet specific needs. The eArc modules facilitate two installation approaches: quick bonding and mechanical mounting.

The quick bonding method allows businesses to install solar solutions with lower labour costs, creating savings and minimal structural modifications. For those preferring a mechanical installation, our modules come with a pre-integrated frame that is compatible with traditional glass module installation methods, seamlessly integrating with existing practices and streamlining the overall process, ultimately saving installation time and costs.

How does your product work from an installation perspective and what sort of training would installers need to put together a system using your technology?

From an installation perspective, SMF modules utilise a ‘quick-bonding’ method, which simplifies the process. Installers require minimal training since the installation does not involve complex mounting systems. A basic understanding of adhesive application and safety measures is sufficient, making it accessible for a broader range of technicians.

Dragonfly modules are designed to be compatible with traditional installation methods, ensuring that they can be easily integrated into existing systems without requiring specialised training for installers.

What implications does the absence of glass in your modules have from a durability and reliability perspective? What sort of testing have your modules undergone and to what extent would they withstand the rigours of harsher environments?

Our products have undergone and passed the same testing the glass modules must pass in order to be connected to grids. This testing, including wind resistance, salt spray and fire resistance tests, ensures they can withstand harsh environmental conditions. The innovative polymer encapsulation offers superior water resistance, anti-glare feature and crack resistance, addressing common failure modes in traditional glass modules.

What do you see as being the biggest opportunities for your lightweight module and what geographic markets are you particularly targeting?

The biggest opportunities for our lightweight modules lie in industrial applications with insufficient load-bearing capacity or roofs that have a membrane roof that cannot be penetrated. Sunman is globally positioned, with shipments to over 40 countries, and has dispatched over 1GW of modules over the past ten years.

We are particularly targeting markets in Europe, North America and Asia-Pacific. The modules effectively address the challenges of traditional PV modules. Moreover, eArc modules can easily integrate with innovative solutions, making them ideal for applications in balconies, carports, transportation, building-integrated photovoltaics (BIPV), mobile energy and off-grid applications.

In Europe, the policy environment is tightening to encourage buildings to become more sustainable, which should help stimulate demand for the kind of product you’re offering. What other policy or market drivers could affect your products?

The European Union has aggressive targets to meet its net-zero goals, which incorporates renewable energy meeting over 50% of its energy demand by 2030. The building of utility-scale solar parks faces challenges around land availability and transmission infrastructure. Sunman’s lightweight solar modules will help transform industrial parks into solar parks, as these systems are located close to load centres, can utilise existing transmission infrastructure and do not require the use of agricultural land.

Given the limitations of traditional glass modules in commercial and industrial settings, to what extent could you foresee some kind of split in the market between modules suited to, say, utility-scale projects and those tailored for rooftop applications?

Sunman believes that this is a pivotal time in the module manufacturing landscape as we predict an ’evolutionary split’ in manufacturing techniques, where manufacturers develop products that are specifically manufactured for rooftop applications, rather than adapting utility-scale modules for commercial and industrial rooftops.

There are other technologies coming down the pipeline, such as tandem perovksites. Do you see those as a threat or opportunity?

While technologies like tandem perovskites present potential competition, I view them as an opportunity for the entire PV industry to evolve. Innovations in solar technology can drive overall growth and demand, benefiting all players in the market. Our focus remains on leveraging our unique advantages in lightweight and flexible modules to carve out a substantial niche. By focusing on these innovative solutions, we aim to lead the charge in making solar accessible and practical for a wider range of applications, embodying our vision of ’PV Everywhere’.

Sunman Energy’s lightweight rooftop PV modules will be the focus of a webinar hosted by PV Tech on Wednesday 30 October, 9am GMT. Details on signing up to the webinar are available here.