As 2021 draws to a close, PV Tech is reviewing the year in solar, reflecting on some of the biggest stories and hottest trends of the last 12 months. Part one of our year in review can be read here, but today we look at the top stories of Q2 2021, as supply chain headwinds began to bite.

Supply chain headwinds are, of course, nothing new for the solar industry to contend with. Polysilicon prices have spiked before, while various other materials and components have too experienced periods of peaks and troughs. It wasn’t until Q2 2021 that it was revealed quite how profitable solar glass had been the year prior, with profits topping US$1.25 billion in the year.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

But Q2 2021 saw polysilicon prices spike particularly high, to levels not seen in years. With demand for solar-grade polysilicon far outstripping supply, a shortage of the raw material sent prices soaring to more than double the price seen prior to the Chinese New Year in February, prompting calls for state intervention to ease what was quickly nearing an industry-wide crisis.

Prices throughout the value chain quickly moved north, with LONGi – fresh off the back of confirming a new module shipments record for 2020 – hiking its prices in mid-May and many manufacturers following suit. An earthquake that rattled wafering facilities owned by TZS and LONGi just a week later further exacerbated the issue, and the industry was forced to closely monitor capacity utilisation rates on the back of sky-high prices. Utilisation rates would later fall drastically as headwinds continued to mount.

It wasn’t just polysilicon, either. The cost of other materials, perhaps most notably steel, jumped as worldwide economies recalibrated from the shock of the pandemic in 2020. This implicated tracker manufacturers, with Array Technologies forced to withdraw its guidance for the year after recording an “unprecedented” increases in material costs.

For some, the industry headwinds in China – as well as mounting scrutiny related to allegations of forced labour and the origins of the industry’s polysilicon supply – fed into renewed scrutiny over just how prevalent ‘Made in China’ modules are for the solar industry. With more than 90% of PV modules still made by Chinese manufacturers throughout Southeast Asia, the issues felt this year led to some rather frank discussions about the need – or at least appetite – for manufacturing bases to be established outside of Asia. Our own Finlay Colville explored that subject in one of our most-read blogs of the year, here.

That discussion would be drawn into even starker focus towards the middle of the year, when the Biden administration in the US would begin a clampdown on polysilicon imports linked to forced labour allegations, firing the starting pistol on a list of trade actions that would grow into the second half of 2021.

As our first part of this year in review covered yesterday, the Biden administration took office at the start of the year and quickly went about restoring the country’s climate credentials. Strapping rocket boosters to the US’ green economy was a central commitment of Biden’s during his election campaign, and at the start of Q2 the president followed through, confirming his intent to extend the solar investment tax credit by 10 years as part of a slew of measures to grow the US’ domestic solar industry.

The US market, or at least the policy machinations affecting it, would be a consistent topic over the course of 2021. Another topic of much discussion was the industry’s transition to n-type technologies. PV Tech’s in-house market research team assessed in May of this year how n-type investment would dominate the sector by 2024, however a walk around the show floor at this year’s SNEC exhibition in June would be proof enough that the n-type transition was very much underway.

Our Chinese editorial team were on hand to cover the exhibition for those who were unable to travel, detailing the events live on day one, day two and day three. All of our coverage from SNEC 2021 can be found here, while our library of exclusive video interviews recorded at the show can be found here.

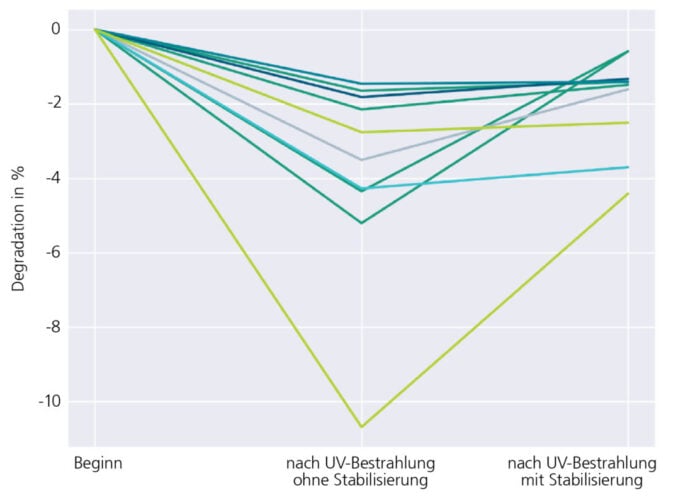

While industry events and trade shows often highlight the technology potential of solar PV, it’s perhaps rare that they truly highlight the issues affecting asset owners and operators day to day. Unfortunately for solar PV, this would become evident after two reports – insurance firm kWh Analytics’ 2021 Solar Risk Assessment and PVEL’s 2021 Module Scorecard – revealed how modules were degrading quicker in the field than they were supposed to, leading to chronic asset underperformance.