Vikram Solar has completed a new 1.3GW solar module manufacturing facility in Tamil Nadu, India, taking its total manufacturing output to 2.5GW.

The new facility constitutes the first phase of planned capacity expansions earmarked for Tamil Nadu after the company signed a Memorandum of Understanding with the state’s government last summer.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

Further additions, including wafer and cell facilities, are expected to be developed over the next four years.

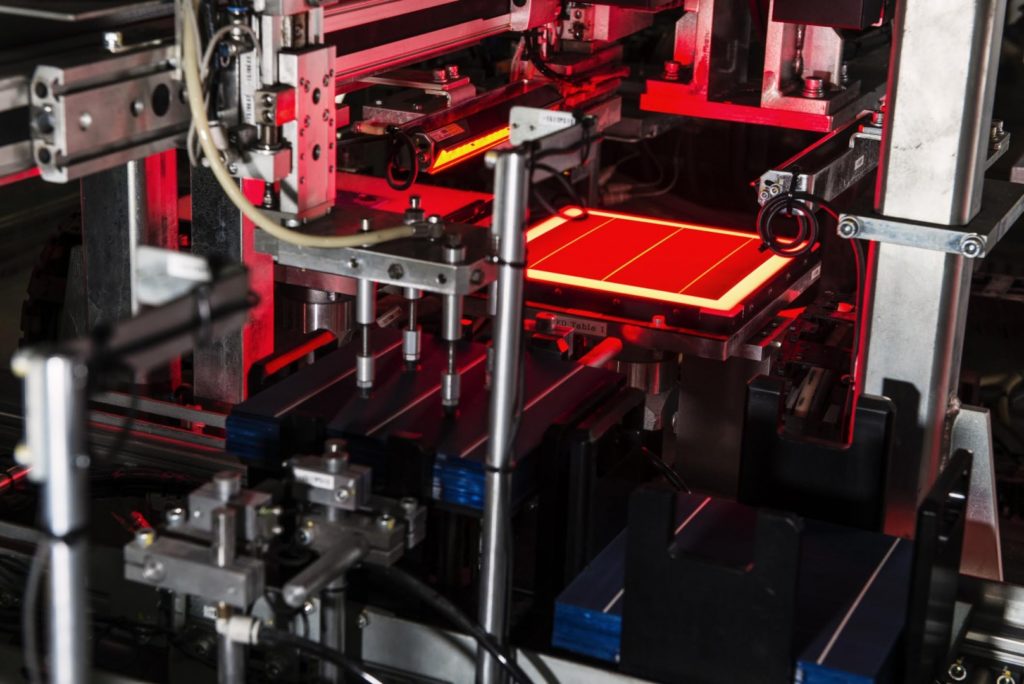

The India-based module manufacturer inaugurated the new facility today (20 July 2021). Its manufacturing lines are capable of accommodating modules featuring M12 (210mm) cells as well as bifacial panels.

Vikram is to use the facility to produce modules with peak power outputs up to 640W, the manufacturer said.

Vikram added that the facility’s location, in close proximity to a port in India’s southern state, would enable faster and more cost-effective transportation. The manufacturer also said it has incorporated digital technologies and artificial intelligence-enabled inspections to reduce panel-level defects during assembly and help reduce waste.

Gyanesh Chaudhary, managing director at Vikram Solar, said that the increase in demand for solar modules, coupled with a desire for more diversified supply chains, presents a “huge opportunity for indigenous solar manufacturing”.

“We believe, our new facility further strengthens not just Vikram Solar but the Nation’s solar manufacturing prowess and ecosystem. Apart from bridging the demand-supply gap for modules, our state-of-the-art facility will propel technological innovation, job creation and aid India’s renewable energy targets,” he said.

Having originally set a target of installing 100GW of solar generation capacity by 2022, a target the country will now miss, the Indian government has moved on to a target of installing 450GW of renewables by 2030, 300GW of which is to be solar PV. Alongside this ambition is an aim to stimulate a domestic solar manufacturing industry in the country, achieved by a raft of measures including a basic customs duty on solar imports and a production linked incentive for solar developers using components manufactured in India.

Vikram said the added capacity would allow it to become India’s largest solar module manufacturer, however Chaudhary also lauded the facility’s benefits in acting as an R&D centre for next generation solar module technologies.

Vikram owns and operates an existing 1.2GW module assembly facility in West Bengal and claims to have shipped 3.5GW of solar modules globally to date.